|

Our Assembly

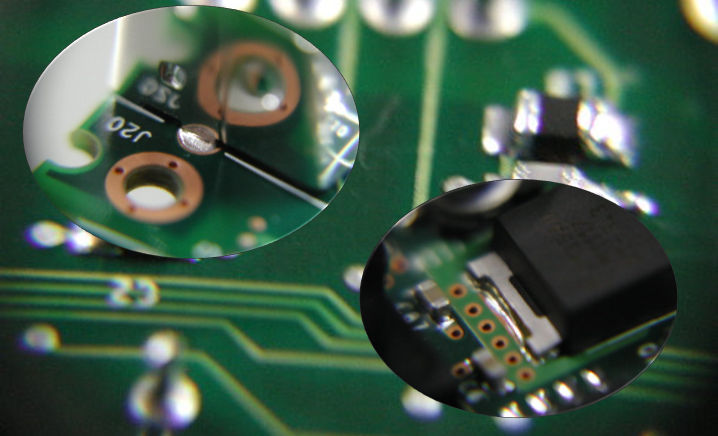

Fully compliant to RoHS, our assembly lines comprises of surface-mount (SMT), reflow and double reflow, through-hole wave soldering line; and the BGA Rework machine. |

| Analysis and Testing

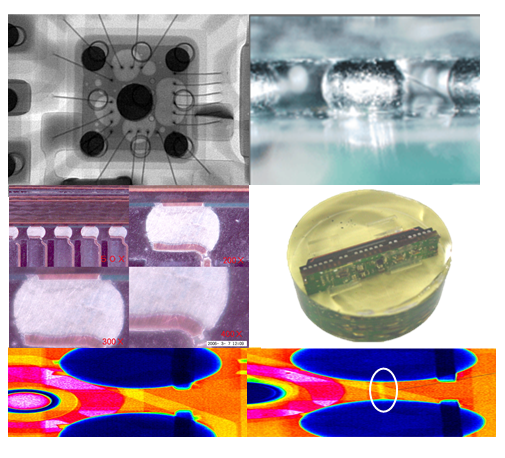

We offers in house analytical and testing services at our facilities. Some of the capabilities are: – Thermal stress cycle testing – Vibration, shock and drop testing – Environment testing – Waveform testing – Automated Optical Inspection – Visual Inspection – Destructive solder analysis – Non-destructive 3D X-Ray Analysis – In-circuit testing using fixtureless tester, and more |

|

Today, if you send us the Gerber files and Bill of Materials, we are almost ready to purchase the material to help you build the boards.

With no obligation, feel free to drop us your enquiry.

3D-X-ray and CT scan

Fixtureless Tester