Every ODM/OEM manufacturing project begins with a consultation with our vertical OEM Account Team to offer each client a customized solution with an emphasis on total product development. We support your product throughout the entire ODM/OEM process to ensure brand identity and maximum product continuity, allowing your company to focus on its core competencies.

You can be confident you will have complete and easy access to the Dynapower ODM/OEM team to provide you with a turnkey solution covering product design, manufacturing, global logistics, and worldwide support. Schedule a free consultation today!

Our Process

| Phase 1: Design | ||

|

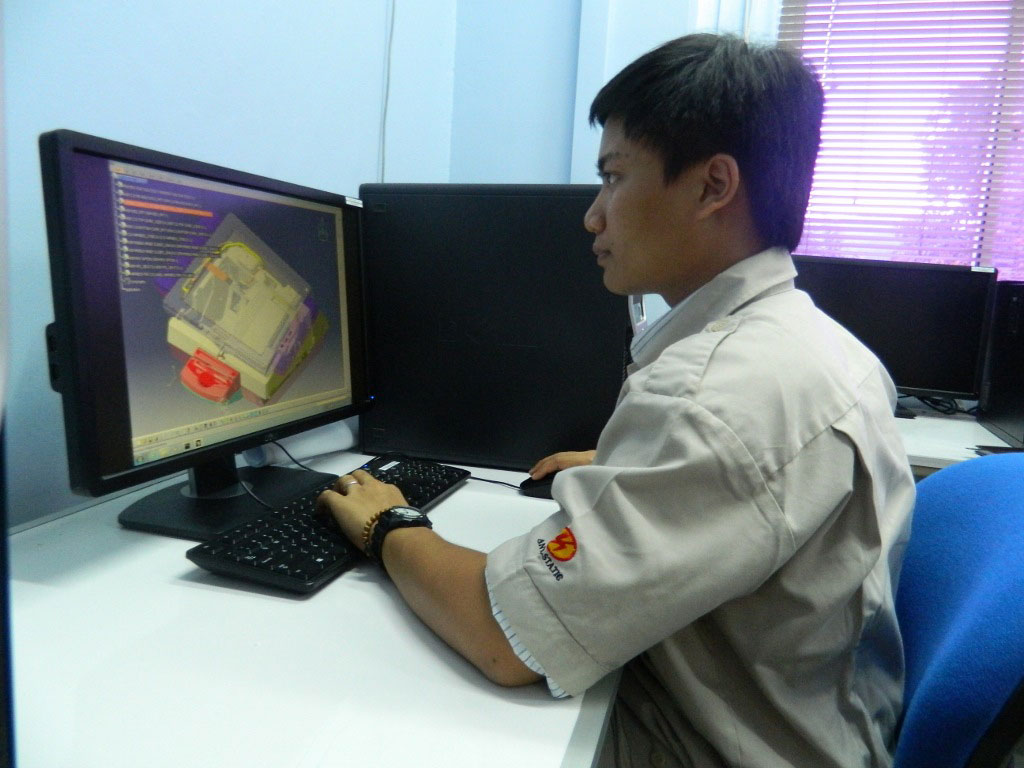

DESIGN: Every project begins with an OEM Consultation where you tell us the desired form factor, performance specifications, life cycle, desired shipping destinations and compliance requirements. Our Team will work with you to design and engineer a customized platform that will meet all your needs.

|

|

|

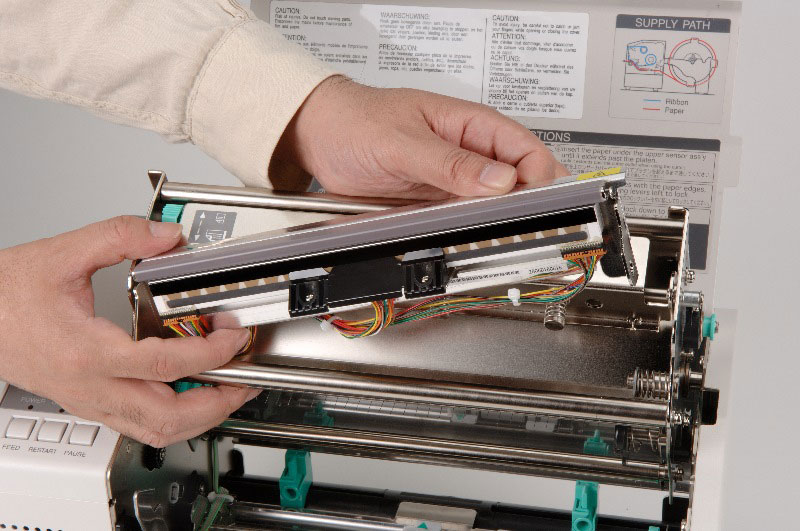

PROTOTYPE: After the hardware specifications are approved, we will begin prototyping the systems with your exact specifications. Once the hardware configurations have been thoroughly tested, we will places the Bill of materials into revision control and step-by-step manufacturing process instructions are created | |

|

BRANDING: We will works with you to achieve your desired branding and appearance of the systems. From custom bezels, faceplates, labels, and chassis to custom box packaging, we have a wide range of options for you to choose from to achieve the look and feel you desire to enhance your brand identity. | |

| Phase 2: NPI (New Product Introduction) | ||

|

MPI and PROCESS FLOW: Manufacturing Process Instructions and Process flows are created at this stage, where we note special requirements such as label placement, custom serial number, MAC address collection or software-specific requirements. | |

|

MANUFACTURING: Your system are manufactured to your exact specifications via our Harsh Environment Manufacturing Process Stage 1: Individual component Testing Stage 2: System Assembly Stage 3: High-Temperature Burn In Stage 4: Functional Testing Stage 5: Final Quality Assurance Program |

|

|

Every product from us are manufactured to the highest ISO 9001 manufacturing standards to ensure consistency and quality. |

||